Specialist marking tools

Marking/Cutting/Mortise gauge:

- Used to mark/dent a piece of timber parallel to the edge

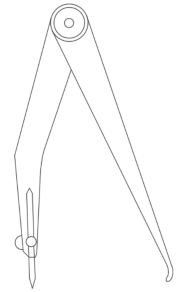

Odd leg callipers:

- Used to mark a line on an edge/step on a peice of metal

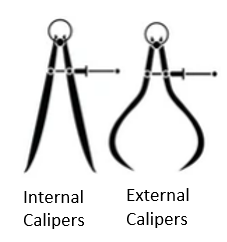

Internal callipers:

- Used to measure the internal diameter of a tube/pole

External callipers:

- Used to measure the outsude diameter of a tube/pole

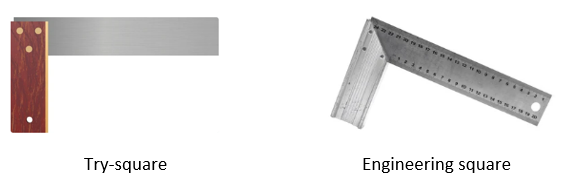

Try-square:

- Used to mark a line 90o to a piece of timber

Engineering square:

- Used to mark a line 90o to a piece of metal

Micrometre:

- Used to measure a small distance/thickness between its tqo faces, one face can be moved to measure different distances

Vernier callipers:

- Used to measure internal/external measurements very orecisely

Densitometer:

- A machine which can be used to measure the optical density of a photographic/semi-transparent material

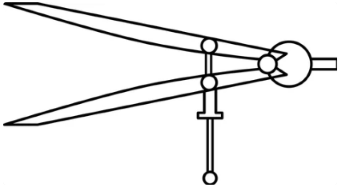

Dividers:

- Used to mark circles/curves on a piece of metal

Jigs:

- A jig is used to control the motion of a tool

| Advantages | Disadvantages |

|---|---|

|

|

Fixtures:

- Used to support/hold the workpiece in place

| Advantages | Disadvantages |

|---|---|

|

|

Go-no-go gauge:

- A go-no-go gauge is a tool used to check a piece of work is the correct size against its allowable tolerance